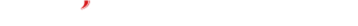

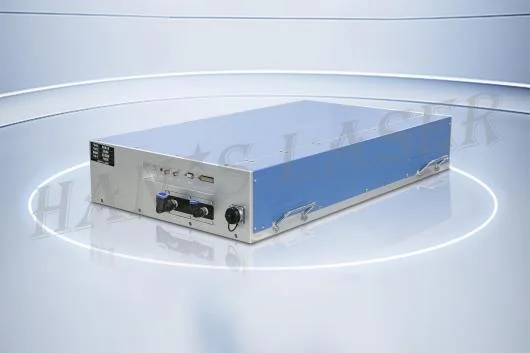

Laser Source| Technological innovation leading the new era of precision processing 50W infrared femtosecond laser

As the global manufacturing industry accelerates its digital transformation and consumer electronics continuous upgrades and iterates, precision processing technology is facing unprecedented opportunities and challenges. Especially in high-end manufacturing sectors such as 3C electronics, semiconductors, and medical devices, demands for processing precision, efficiency, and environmental performance are becoming increasingly stringent. Against this backdrop, Han’s Laser, as a leading enterprise in laser processing, has leveraged its years of technological accumulation to successfully launch a 50W infrared femtosecond laser—a groundbreaking industry-leading product—through its Ultraviolet and Ultrafast Laser Centre. This innovation brings revolutionary solutions to the manufacturing processing sector, enabling customers to achieve scalable and customized production.

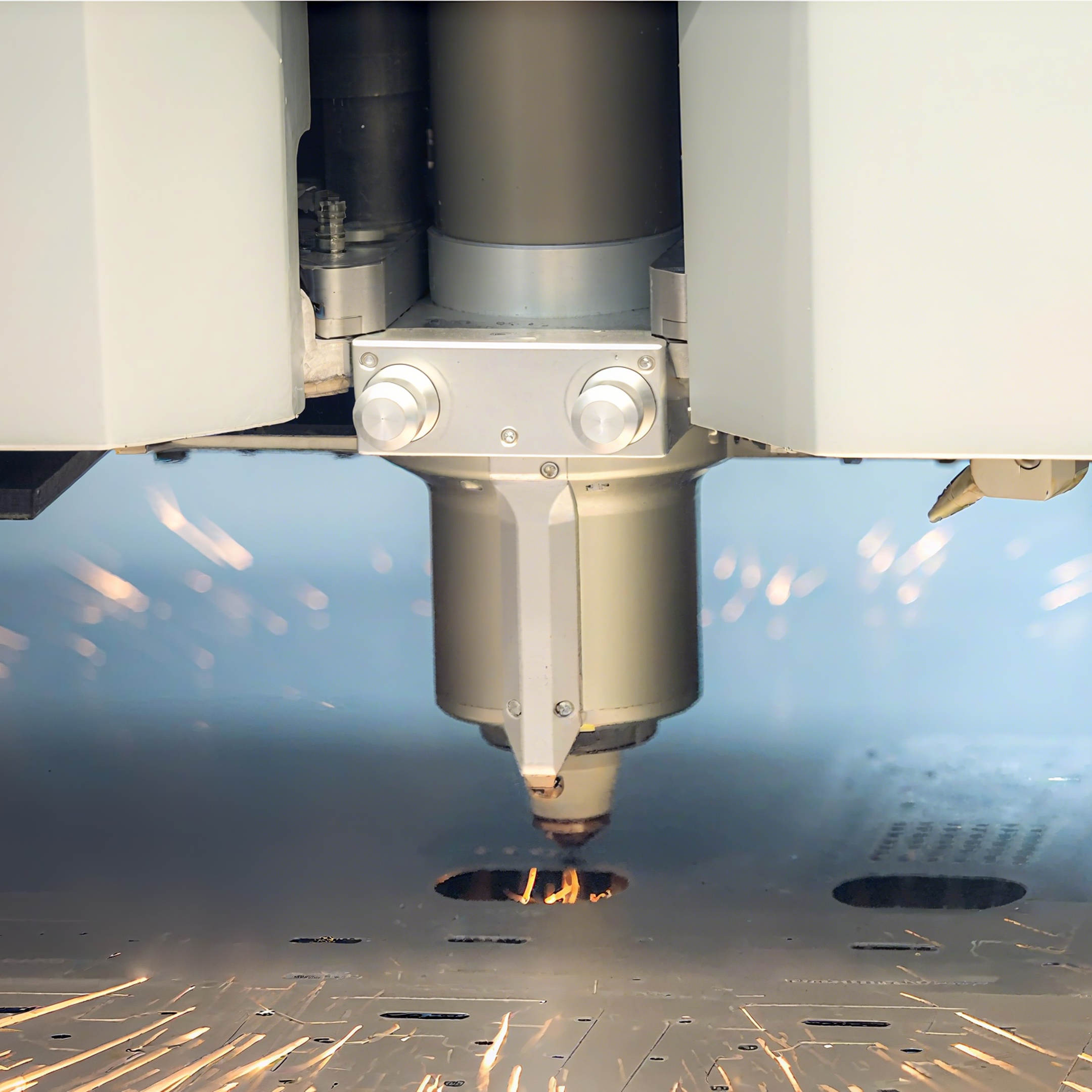

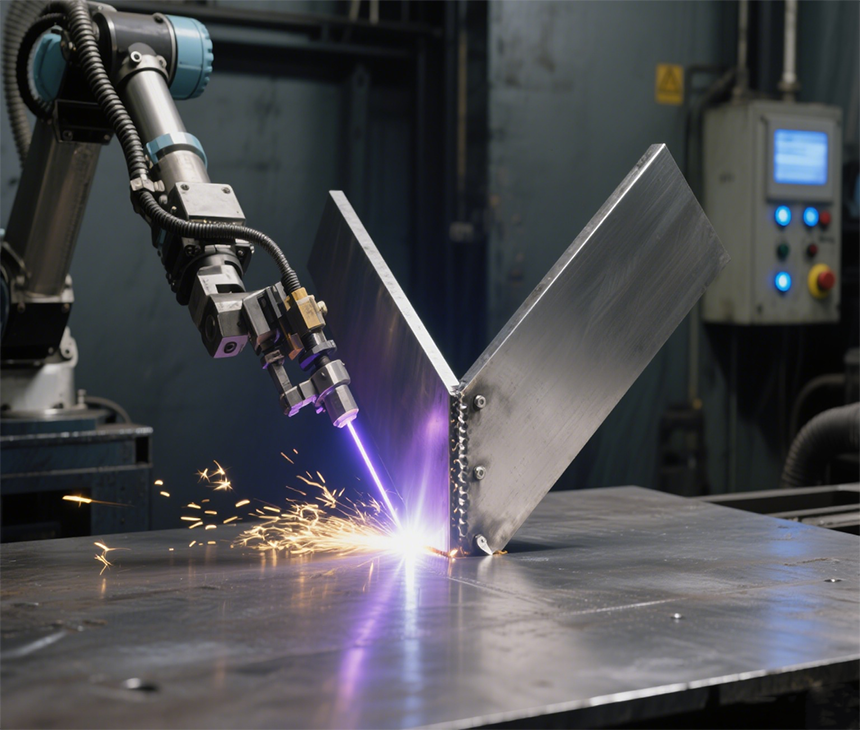

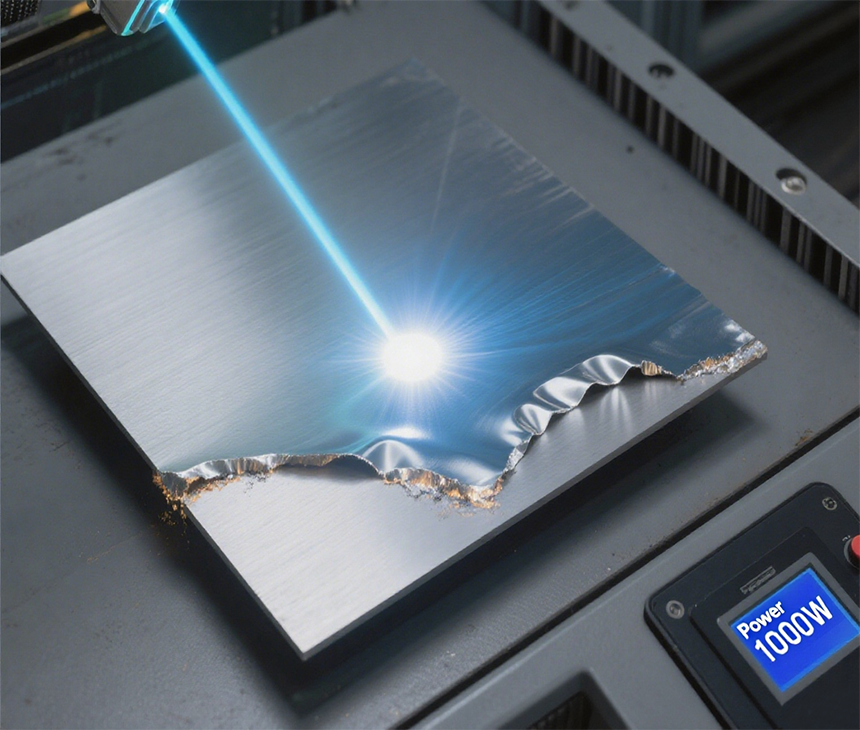

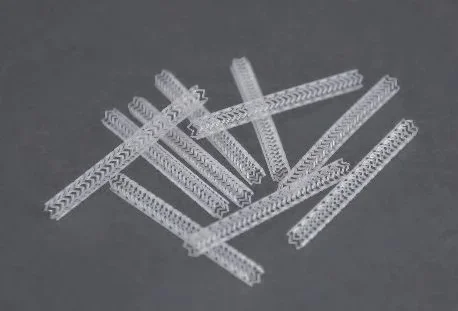

Currently, laser processing technology has evolved from traditional millisecond and microsecond levels to the current femtosecond era. Compared to nanosecond (10⁻⁹ seconds) and picosecond (10⁻¹² seconds) lasers, femtosecond lasers (10⁻¹⁵ seconds) utilise their ultra-short pulse characteristics to achieve a ‘cold processing’ effect during processing, with the heat-affected zone (HAZ) controllable within the micrometre range. This characteristic gives it a significant advantage in the processing of brittle materials: the processed edges exhibit no micro-cracks, no molten residues, and no material phase changes, truly meeting the industrial demand for ‘ultra-fine processing.’

As products and markets continue to evolve and update, the application requirements for lasers are becoming increasingly diverse and complex. Among these, the penetration rate of femtosecond lasers in the field of precision micro-processing is steadily increasing, demonstrating strong market demand. Han’s Laser's all-fibre femtosecond laser adopts an all-fibre amplification scheme, combined with a self-developed femtosecond seed source, and achieves narrower compressible pulses through precise control of dispersion parameters. Compared with similar laser products, it has achieved breakthroughs in multiple key performance indicators, with significant advantages: smaller heat-affected zone, higher beam quality, more precise processing results, higher precision, and broader application scope.

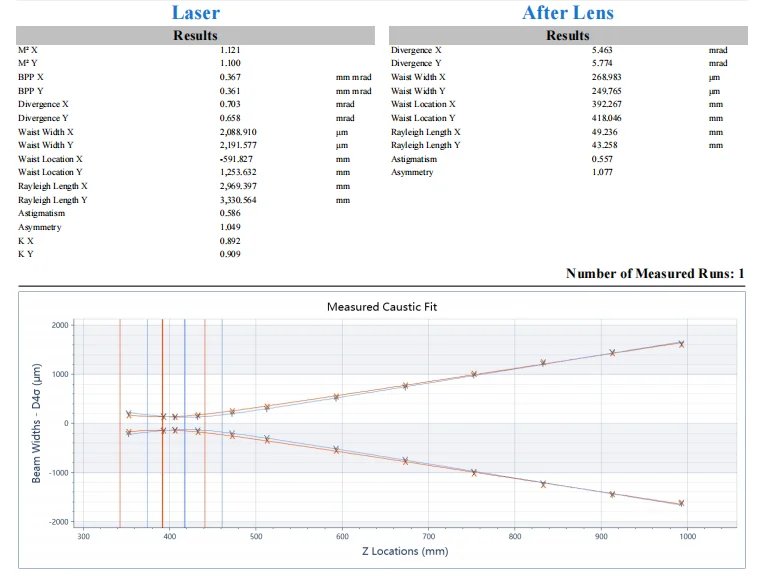

Excellent beam quality

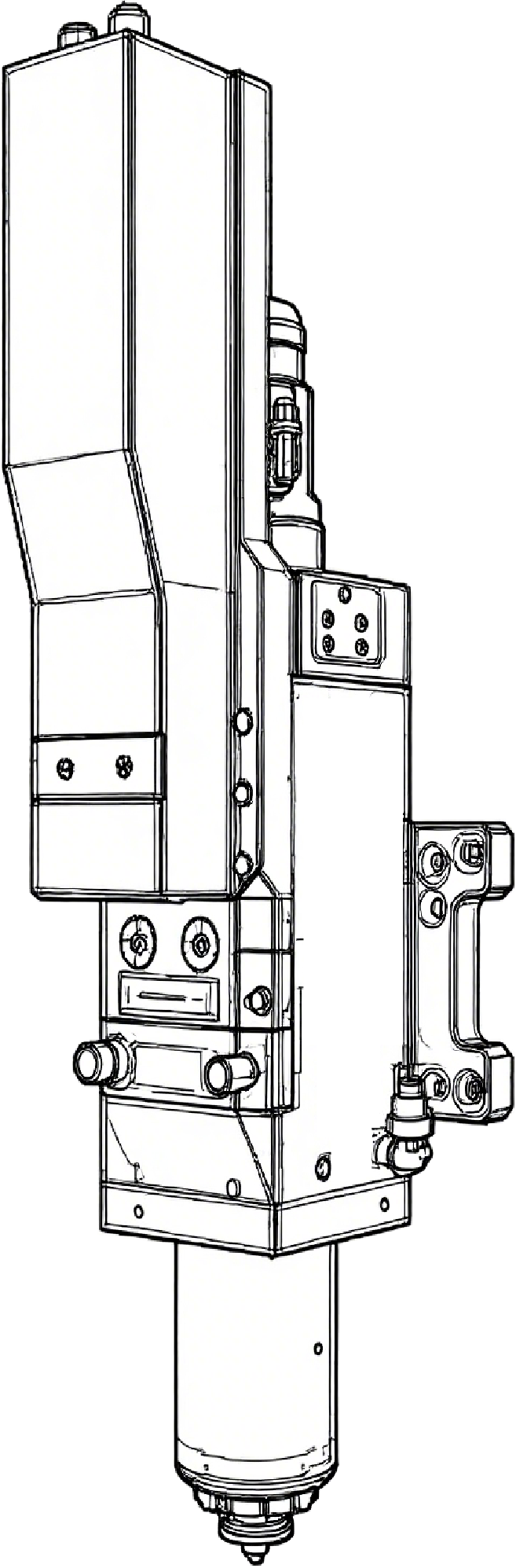

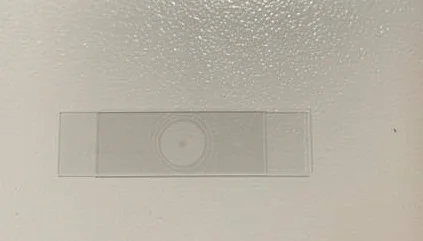

Through a combination of precisely designed preamplifier and power amplifier stages, the fibre femtosecond laser maintains excellent beam quality (M²≤1.3). During processing, it achieves better focusing effects, significantly improving the processing efficiency of materials such as glass and controlling chipping during processing.

Narrow pulse width

Narrow pulse width with dynamically adjustable width (300fs-10ps continuously adjustable).

Easy to operate and highly adaptable

The control system and software developed for this femtosecond laser feature a user-friendly human-machine interface design and simple operation, enabling real-time monitoring of the laser's status. Customers can select between internal and external control modes according to their processing requirements.

Stable beam directivity

Beam pointing stability closed loop correction (≤±20μrad)

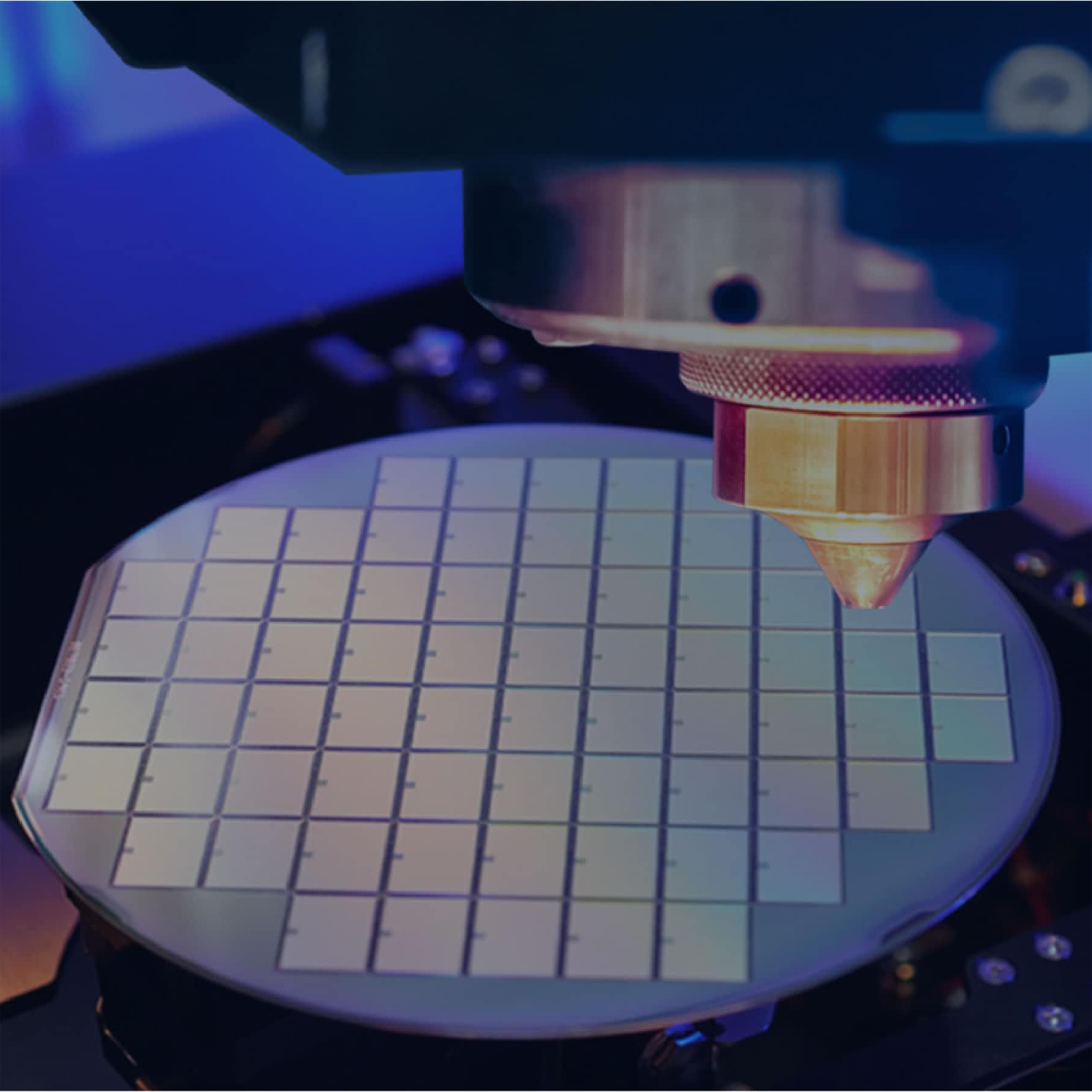

The 50W infrared femtosecond laser has demonstrated outstanding processing performance in multiple high-end manufacturing fields: cardiovascular stent cutting, semiconductor material processing, PCB material cutting and scribing, drilling, slotting, and chamfering of glass and ceramic materials in the consumer electronics industry, drilling of photovoltaic solar backplate glass, and two-photon micro-nano processing.

The successful launch of the femtosecond laser is attributed to Han's Laser's significant advancements and technological innovations in device development. Each product is designed with a professional approach to directly address customer needs and deliver superior value, ensuring an optimal user experience in practical applications. The Ultraviolet and Ultrafast Laser Centre will continue to intensify its efforts in innovation and research and development, focusing on achieving higher power, greater pulse energy, peak power, narrower pulse width, and expanded capabilities in the green and ultraviolet wavelength bands.

In the future, with the widespread adoption of emerging technologies such as 5G, artificial intelligence, and AR/VR, femtosecond laser processing technology will undoubtedly see even broader application prospects. Han’s Laser will continue to deepen its ‘industry-academia-research-application’ collaborative innovation mechanism, focusing on overcoming the industrialisation bottlenecks of high-power femtosecond lasers, to drive China's precision manufacturing industry towards high-quality development and inject new technological momentum into ‘ Intelligent Manufacturing in China.’